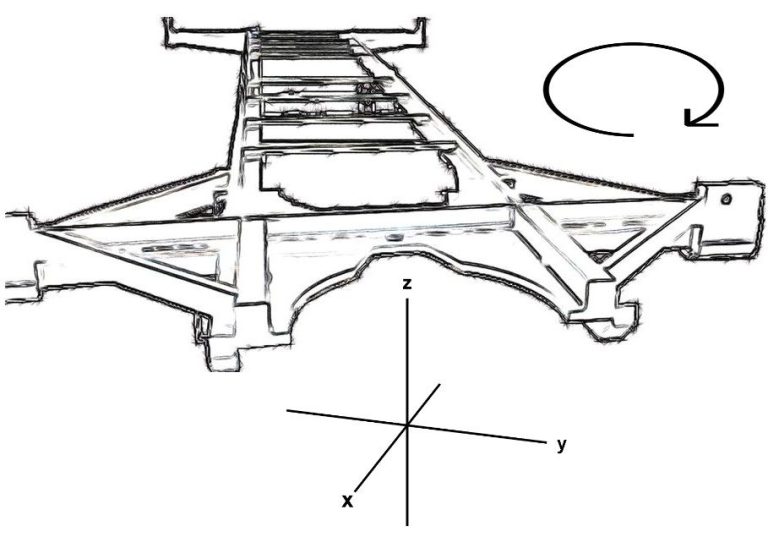

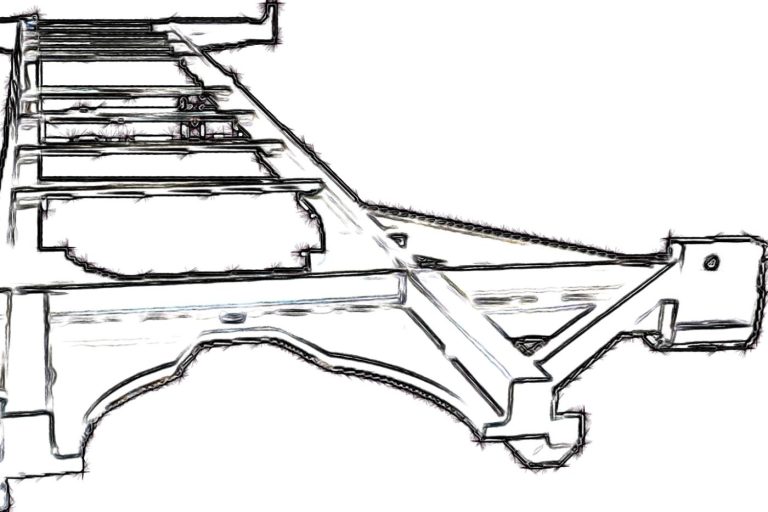

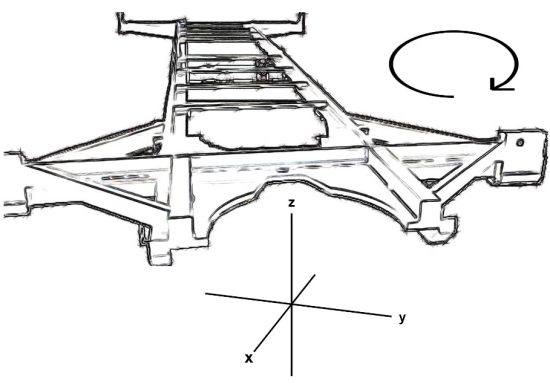

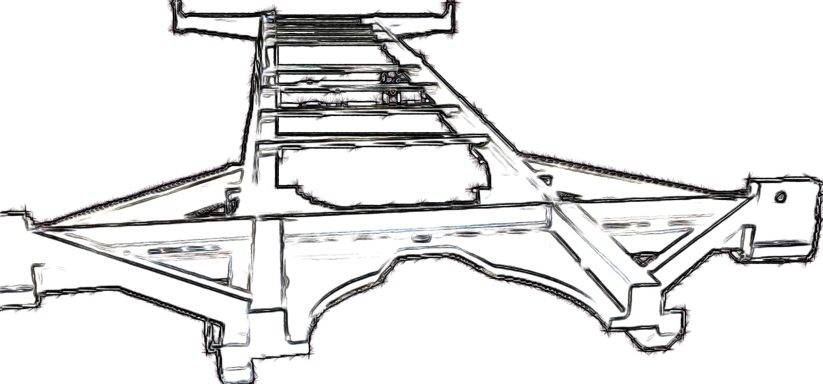

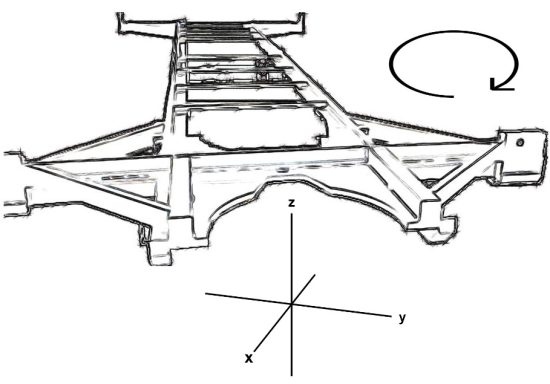

Sea shipping container system which allows a device in the form of a patented sled design connect onto the ISO sea shipping container. The boks sled (Sea Container Sled) allows for the mobilisation and de-mobilisation of the entire unit (sled and sea shipping container) primarily designed for a roll-off tractor. The Sea Container Sled having a primary load and tow eye at one end, and a secondary tow eye at the rear of the apparatus; allows the Sea Container Sled the ability to move, slide, lift and load a loaded ISO or customized sea shipping container onto the tractor applications noted and use equipment to easily move the Sea Container Sled apparatus across any terrain and limit any damage done to the sea shipping container maintaining its ISO rating through out its lifecycle as long as it is attached to the Sea Container Sled.

ARTICLES

analysis of a fixed container weld on application

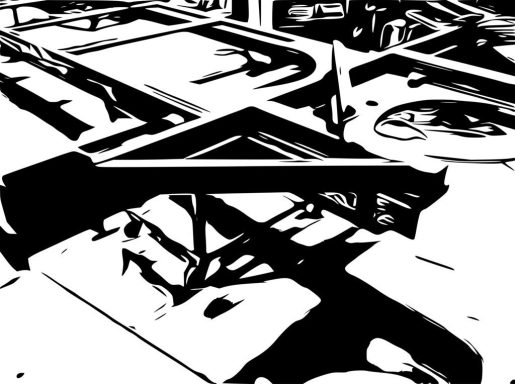

We have had lots of opportunities to analyze fixed weld on application as we have had to move these applications as well in our area of work (rescue, recovery, haulage etc).. here are some annecdotes of defficiencies based on our experiences.

- When the weld on structure is broken the container can no longer be moved with a roll off truck.

- Without front corner braces the container will twist and bend when loaded heavily.

- The front of the weld applications do not push debris out of the way to protect the container and materials/equipment inside. We often find the ribs and floors ripped out or damaged with the weld on applications.

- When the container is broken the weld on structure cannot be moved to another container for continued use.

- Many times the weld on structure does not protect the container.

- Often the weld on applications require customization of the ISO rated container which is a liability concern as an engineered design has been tampered and mofied and really should not be handling the ISO rated carrying weight.

- Because the weld on applications do not protect the container as well as the böks sled we often find that the door locks and main frame members are all rusted out and holes are often punched in the core frame from mishandling/misuse.

- Analyzing the amount of custom work done with the weld on applications we see no reason why any operator will simply choose the böks sled instead of the weld on applications which cannot be used in perpetuity.

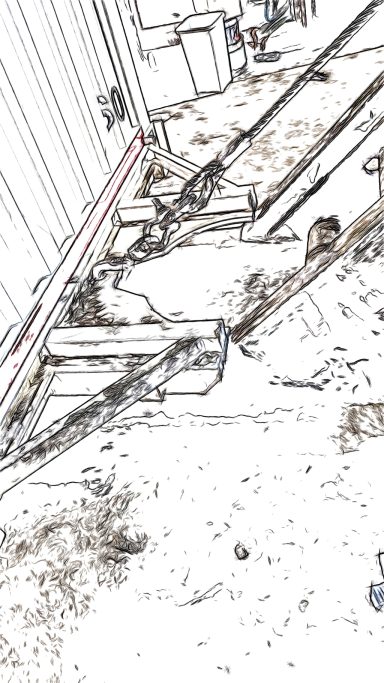

- We have often seen catastrophic failure from mishandling like the photo above. This makes moving the weld on application tough to move, hard to fix (in the field especially) - i.e. how are you to fix the ribs and rails on a fully loaded container on a construction site? moving is next to impossible (most often it is not possible and operators do not want to carry damaged loads) ---- the böks sled addresses these issues; as it can be easily dismounted or swapped out on the jobsite and taken back to the weld shop for easy cheap repair for most people with some mechanical ability to fabricate and weld.

- The böks sled gives you handling points so you are able to manage and move your operation easily using any construction vehicle... where as the weld on applications are very limited and are tricky to handle. (i.e. lack of tow points, no guards to protect container when loading etc.)

- The böks sled provides push guards to protect the container for forward and reverse dragging whilst pushing debris out of the way and also protects the corners of the ISO container structure when pivoting/rotating. The handling characteristics of the böks sled far supersedes that of any weld on application.

- In just one operational incident of a weld on structural failure the the böks sled bolt on application would be paid for and the recoup of operational $'s is realized. We found the difference in cost is insignificant when calculated; factoring in the multiple operators required, multiple machines required, multiple trades required, multiple tools required, safe location to conduct the work etc.

- We often come across weakened floors and structures in the containers as the weld on systems do not push the debris ouf of the way when handled and often the floor joists are torn or damaged due to mishandling.

- We found when looking at the fabrication of the weld on systems that the technician will often create traps for dirt and moisture to build; thus rotting out the container structure and making it dangerous for use in the field.

Another example of a container that has been just dragged around using weld on systems.. where the corners collected debris and rusted out from the top down and bottom up.

- Without a sled you have debris filling the corners which traps moisture and often corrosive waste material from the job site which destroys the container structure.

- A completely trapped side with debris; it wont take long for the seams to open up, corrode and floors to rot out.

- Partially covered side rail of a container.

- A trapped door with debris. The hinges, gaskets and door will be inoperable soon without a böks sled beneath it. Water will drain into the container due to the debris pile and the gasket leaking.

- Backside of the böks sled mounted to an container. Even pulling in reverse limits the debris pile up against the access doors.

- Pulled for miles weekly on this jobsite. The böks sled pushes all light and heavy debris out of the way.

- Pulling this along during road/rail construction this böks sled self levels on grindings, compacted dirt and gravel. We took the resting points of the sled into consideration in the design for this very purpose.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.